LEDAS Blog

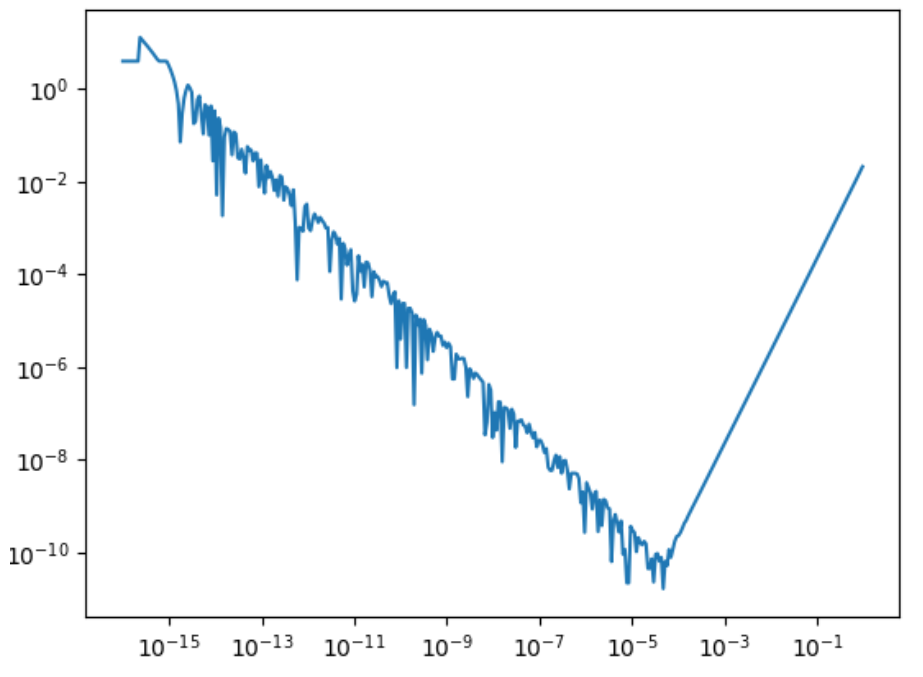

Geometric modelling is typically based on numerical methods that calculate derivatives of functions.

One significant example is constraint solving, which involves solving systems of non-linear equations. Popular classes of numerical methods, like the Newton Method, are based on calculating the Jacobian matrix for a system, i.e., the values of partial derivatives of each equation's expression by each of the variables of the system.

Another fundamental use case is calculating the intersecting curve between two surfaces in 3D space. This is reduced to solving a small system of three non-linear equations with four variables – two parameters of each of the two surfaces.

Both these examples illustrate the fact that the functions we need to differentiate can be quite complex and diverse: different geometric constraints and types of surfaces might ...

LEDAS Opens New Office in Israel

Jul 24, 2023The LEDAS Group recently opened a new office in the metropolitan area of Tel Aviv. This location is in the central business district of Israel and will help us to better deal with customers in Israel and globally.

Israel is widely known as one of the world leaders in engineering software through the presence of big development offices of established CAD/CAM/CAE vendors, as well as startups. This makes the country a major hub of the world of engineering software.

We have a long history of working with Israeli companies. Starting in 2004, our very first license of the LGS constraint solver was made with an Israeli company, Proficiency, which today is part of ITI, a Wipro company.

At the other end of the timeline, our most recent agreement was ...

We’ve launched our Web site with a new language, this time in German. Through https://ledas.com/de/, we are making information about LEDAS services more visible to potential engineering, design, and manufacturing customers in Germany, Switzerland, Austria, and other German-speaking countries.

Germany is well-known as the leader of European manufacturing, and one of the leaders of manufacturing worldwide. As our company from the very beginning was focused on the European market of engineering software, we managed to get into contact with German businesses rather fast.

Case History: CAM Software Success

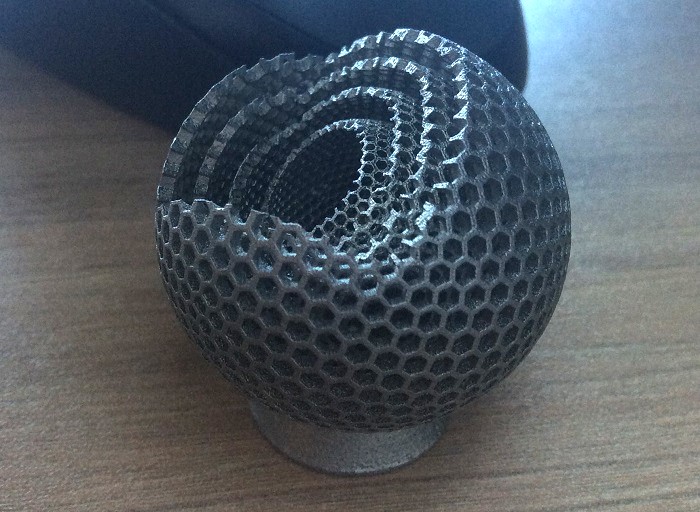

CAM (computer-aided manufacturing), including additive manufacturing, is one of our six areas of expertise, and it is the one with which we have been working with German firms the most.

Our biggest project to date was dedicated to machine ...

Salutations à Tous les Lecteurs Francophones!

Greetings to all French-speaking readers!

Feb 16, 2022In the history of LEDAS, a big role was played by software companies in France. Our company got its start in 1999 by landing work with French CAD vendors. Since then, LEDAS has provided B2B R&D (business-to-business research and development) services to several well-known CAD and CAM companies in France in the field of computational geometry. This early experience helped shape the corporate culture of engineering software development at LEDAS.

Contracts with customers from France have been the longest in the history of LEDAS, two of which worked with us for over a decade. For Dassault Systèmes, LEDAS helped develop geometric constraint solvers and a 3D modeling kernel used by the CATIA mechanical design system. Another contract was done with an award-winning CAM company in the aerospace industry. ...

Pivot Points In the Story of LEDAS

Mar 30, 2021It’s just before our 22nd anniversary on April 1, and looking back at the history of LEDAS, I see that the first years from each decade were, for our company, the really important ones. Often, these years started new stories and finalized old ones.

Arguably, 2011 was the most pivotal year in LEDAS’ history. Let me list the top five events that happened to our company ten years ago:

- Top management changed completely when co-founder David Levin stepped back as CEO and took on the role of Chairman of the Board. A new generation of young managers, aged around 30 years old, now occupied the CEO, CTO, and COO positions.

- Thanks to advice from an industry mate, LEDAS decided to focus mostly on high-quality software R&D (research and ...

Why we use Visitor pattern in C++ CAD projects

Sep 14, 2020One hierarchy, many algorithms

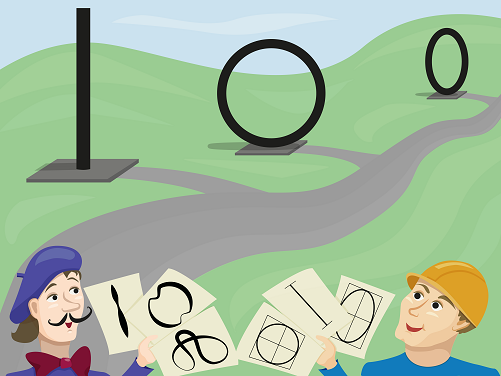

Geometrical modeling projects often contain some form of central hierarchy of objects. A geometric kernel, for example, has a hierarchy of geometric entities. Another example is a geometric solver which has a hierarchy of objects and constraints. Simplified inheritance diagrams for these hierarchies are shown in the figures below.

Many routines/algorithms of other modules need to process all the entities in a hierarchy in a similar fashion, although with different implementation details. So, polymorphism naturally is used with these kinds of hierarchies.

Assuming we are talking about C++ (and this is usually the programming language of choice for algorithmic libraries in CAD), using virtual functions is the first consideration for implementing polymorphic behaviour.

However, a variety of routines applied to the entire hierarchy, ...

While working on LGS, the programmers at LEDAS developed similar software for Dassault Systèmes, which were integrated into CATIA and so are used by hundreds of thousands engineers in corporations like Toyota, Honda, Airbus, and Boeing. Much later, LEDAS was asked to develop constraint solvers that ...